Classification :

Customer Visit

After more than 20 years of ups and downs, Xinxing Casting will continue to write brilliant, and customer recognition is our greatest support! We are willing to work hand in hand with colleagues from all walks of life to create brilliance together!

OUR ADVANTAGE

Brand strength

Ductile tube production base Excellent ductile tubes on the market

Quality-oriented service concept

Independent ductile tube production base in China

Won the trust and praise of the majority of users. After years of development, we have become one of the largest ductile tube companies in the ductile tube market.

Strict technology

We have been engaged in ductile iron pipe business for many years, and we have been engaged in ductile iron pipe business for major steel mills across the country

Our products are complete in variety and specifications, and have quality assurance

We have processing equipment and logistics distribution systems to meet the various needs of customers at any time

After-sales team

Large team size to meet customers’ non-standard customization needs

A team with rich experience in the ductile iron pipe industry

Customized model integrating R&D, production and post-processing

Have a high-quality workforce

After-sales service team

Provide one-on-one personalized product solution demand services

The service concept of creating value for customers

Users are welcome to visit and purchase.

We will repay your trust with high quality!

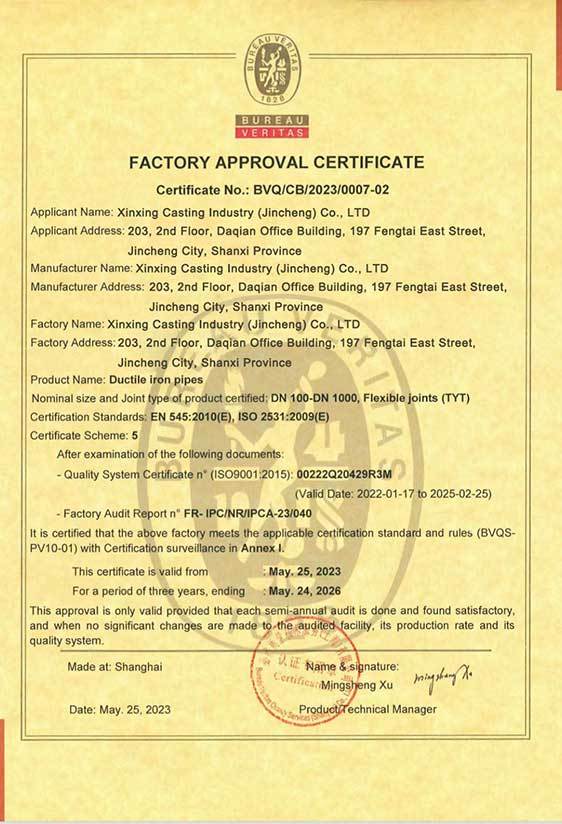

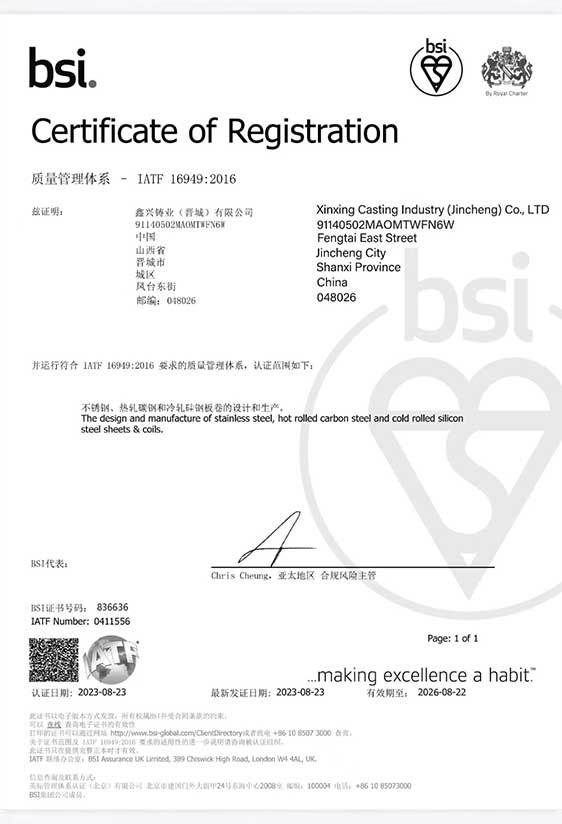

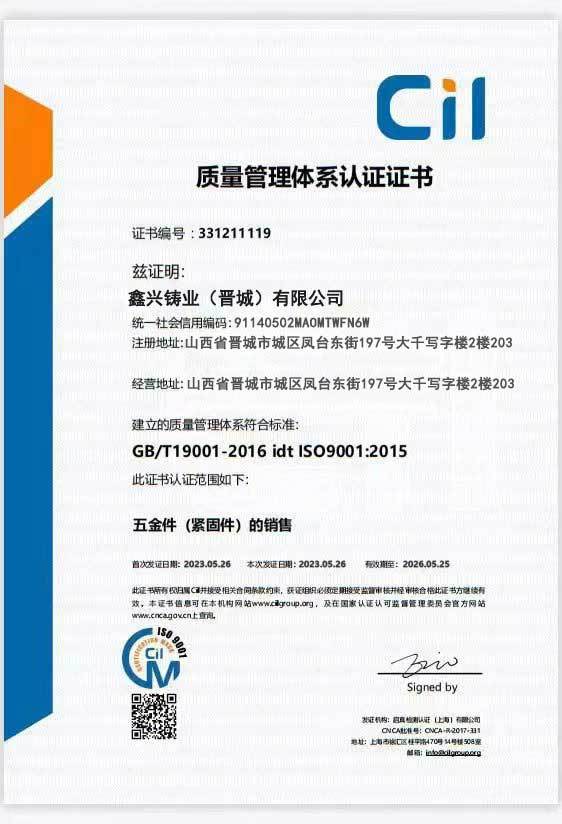

HONOR

RELATED PRODUCTS

GET A FREE QUOTE