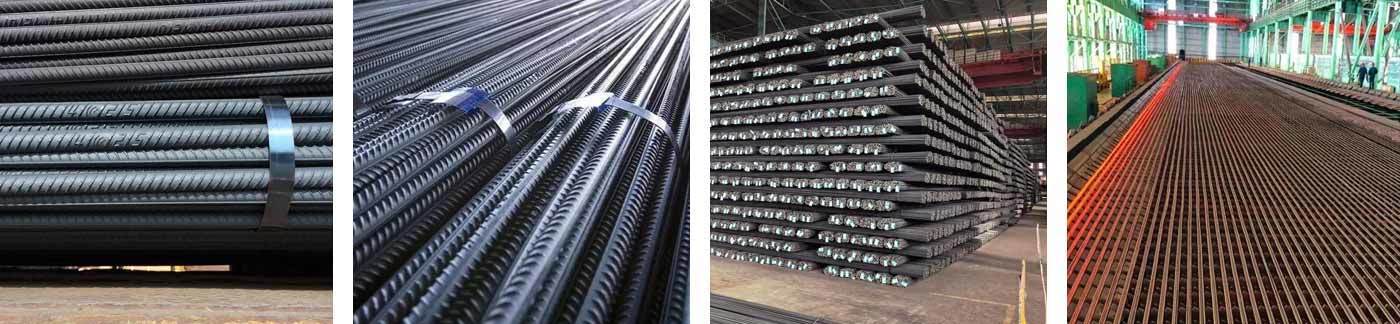

Epoxy Resin Coated Steel Bar

Classification :

Product Details

Epoxy Resin Coated Steel Bar Description

Epoxy resin coated steel bar is an epoxy resin protective coating prepared on the surface of ordinary steel bar by electrostatic spraying powder high temperature sintering process. The coating has excellent chemical corrosion resistance and does not react with acid and alkali. And the coating has anti-permeability, so it can delay the corrosion medium (such as water, oxygen, chloride, etc.) contact with the steel, so that its corrosion resistance life is greatly extended.

China's epoxy coated steel bars adopt national standards GB/T 25826-2010 and Ministry of Housing and Construction standard JG/T 502-2016 (replacing JG 3042-1997). American standards are ASTM A775/A775M and ASTM A934/A934M, and British standard is BS ISO 14654.

The whole life cycle analysis shows that the comprehensive cost of epoxy coated steel bar is very low.

Epoxy coated reinforced concrete structures have a longer life than ordinary carbon steel concrete structures.

Product Parameters

Grade of Base Material Reinforcement | HRB400, HRB400E, HRB500 HPB300 (Hot Rolled Round Steel Bar) | |||

| Coating Technology | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Coating Standard | GB/T 25826-2010, JG/T502-2016 | |||

| Conventional Diameter | 10/12/14/16/18/20/22/25/28/30/32/36/38/40/50mm | |||

Custom Diameter | 6mm-50mm | |||

Standard Length | 6m/9m/12m (Length can be customized) | |||

Use | Anti-floating anchors, bridges, railways, seaports, nuclear power, sewage tanks, petrochemical and chemical projects with corrosion resistance requirements | |||

Chemical Composition of Base Metal

Carbon | Silicon | Manganese | Sulphur | Phosphorus |

0.25% | 0.80% | 1.6% | 0.045% | 0.045% |

Mechanical Properties of Base Metal

Chinese Rebar Code | Yield Strength (Mpa) | Tensile Strength (Mpa) | Carbon Content |

HRB400, HRBF400, HRB400E, HRBF400E | 400 | 540 | ≤ 0.25 |

HRB500, HRBF500, HRB500E, HRBF500E | 500 | 630 | ≤ 0.25 |

HRB600 | 600 | 730 | ≤ 0.28 |

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.

| USA | Japan | Germany | U.K. |

| France | Italy | Spain | Switzerland | China | |

AISI/SAE | JIS | W‐nr. | DIN | BS | EN | AFNOR | UNI | UNE | SS | GB |

A570.36 | STKM 12A | 1.0038 | RSt.37‐2 | 4360 | ‐ | E 24‐2 | ‐ | ‐ | 1311 | 15 |

- | STKM 12C | - | - | 40 C | - | Ne | - | - | - | - |

1015 | ‐ | 1.0401 | C15 | 080M15 | ‐ | CC12 | C15, C16 | F.111 | 1350 | 15 |

1020 | ‐ | 1.0402 | C22 | 050A20 | 2C | CC20 | C20, C21 | F.112 | 1450 | 20 |

1213 | SUM22 | 1.0715 | 9SMn28 | 230M07 | 1A | S250 | CF9SMn28 | F.2111 | 1912 | Y15 |

11SMn28 | ||||||||||

12L13 | SUM22L | 1.0718 | 9SMnPb28 | ‐ | ‐ | S250Pb | CF9SMnPb28 | 11SMnPb28 | 1914 | ‐ |

‐ | ‐ | 1.0722 | 10SPb20 | ‐ | ‐ | 10PbF2 | CF10Pb20 | 10SPb20 | ‐ | ‐ |

1215 | ‐ | 1.0736 | 9SMn36 | 240M07 | 1B | S300 | CF9SMn36 | 12SMn35 | ‐ | Y13 |

12L14 | ‐ | 1.0737 | 9SMnPb36 | ‐ | ‐ | S300PB | CF9SMnPb36 | 12SMnP35 | 1926 | ‐ |

1015 | S15C | 1.1141 | Ck15 | 080M15 | 32C | XC12 | C16 | C15K | 1370 | 15 |

1025 | S25C | 1.1158 | Ck25 | ‐ | ‐ | ‐ | ‐ | ‐ | ‐ | 25 |

A572-60 | ‐ | 1.890 | StE380 | 4360 55 | ‐ | ‐ | FeE390KG | ‐ | 2145 | ‐ |

1035 | ‐ | 1.0501 | C35 | 060A35 | ‐ | CC35 | C35 | F.113 | 1550 | 35 |

1045 | ‐ | 1.0503 | C45 | 080M46 | ‐ | CC45 | C45 | F.114 | 1650 | 45 |

1140 | ‐ | 1.0726 | 35S20 | 212M36 | 8M | 35MF4 | ‐ | F210G | 1957 | ‐ |

1039 | ‐ | 1.1157 | 40Mn4 | 150M36 | 15 | 35M5 | ‐ | ‐ | ‐ | 40Mn |

1335 | SMn438(H) | 1.1167 | 36Mn5 | ‐ | ‐ | 40M5 | ‐ | 36Mn5 | 2120 | 35Mn2 |

1330 | SCMn1 | 1.1170 | 28Mn6 | 150M28 | 14A | 20M5 | C28Mn | ‐ | ‐ | 30Mn |

1035 | S35C | 1.1183 | Cf35 | 060A35 | ‐ | XC38TS | C36 | ‐ | 1572 | 35Mn |

1045 | S45C | 1.1191 | Ck45 | 080M46 | ‐ | XC42 | C45 | C45K | 1672 | Ck45 |

1050 | S50C | 1.1213 | Cf53 | 060A52 | ‐ | XC48TS | C53 | ‐ | 1674 | 50 |

1055 | ‐ | 1.0535 | C55 | 070M55 | 9 | ‐ | C55 | ‐ | 1655 | 55 |

1060 | ‐ | 1.0601 | C60 | 080A62 | 43D | CC55 | C60 | ‐ | ‐ | 60 |

1055 | S55C | 1.1203 | Ck55 | 070M55 | ‐ | XC55 | C50 | C55K | ‐ | 55 |

1060 | S58C | 1.1221 | Ck60 | 080A62 | 43D | XC60 | C60 | ‐ | 1678 | 60Mn |

1095 | ‐ | 1.1274 | Ck101 | 060A96 | ‐ | XC100 | ‐ | F.5117 | 1870 | ‐ |

W1 | SK3 | 1.1545 | C105W1 | BW1A | ‐ | Y105 | C36KU | F.5118 | 1880 | ‐ |

W210 | SUP4 | 1.1545 | C105W1 | BW2 | ‐ | Y120 | C120KU | F.515 | 2900 | ‐ |

Packing and shipping

Customer Visit

After more than 20 years of ups and downs, Xinxing Casting will continue to write brilliant, and customer recognition is our greatest support! We are willing to work hand in hand with colleagues from all walks of life to create brilliance together!

OUR ADVANTAGE

Brand strength

Ductile tube production base Excellent ductile tubes on the market

Quality-oriented service concept

Independent ductile tube production base in China

Won the trust and praise of the majority of users. After years of development, we have become one of the largest ductile tube companies in the ductile tube market.

Strict technology

We have been engaged in ductile iron pipe business for many years, and we have been engaged in ductile iron pipe business for major steel mills across the country

Our products are complete in variety and specifications, and have quality assurance

We have processing equipment and logistics distribution systems to meet the various needs of customers at any time

After-sales team

Large team size to meet customers’ non-standard customization needs

A team with rich experience in the ductile iron pipe industry

Customized model integrating R&D, production and post-processing

Have a high-quality workforce

After-sales service team

Provide one-on-one personalized product solution demand services

The service concept of creating value for customers

Users are welcome to visit and purchase.

We will repay your trust with high quality!

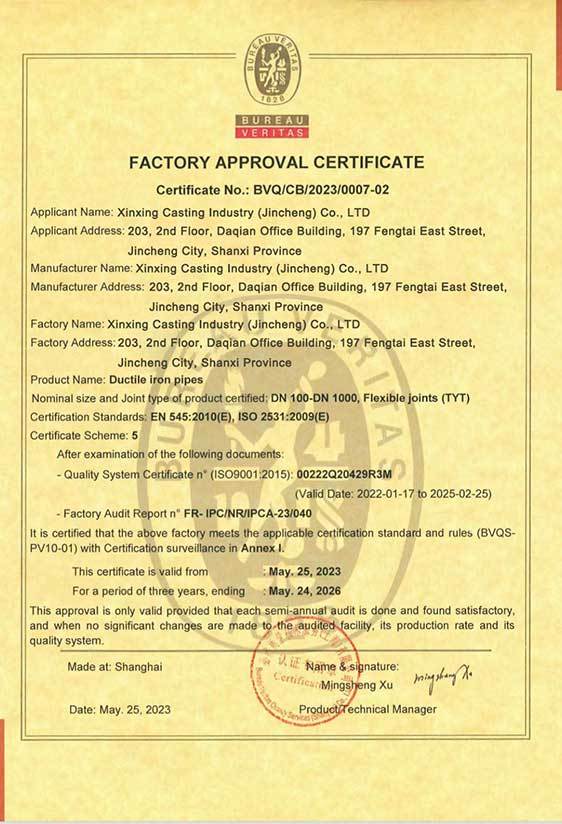

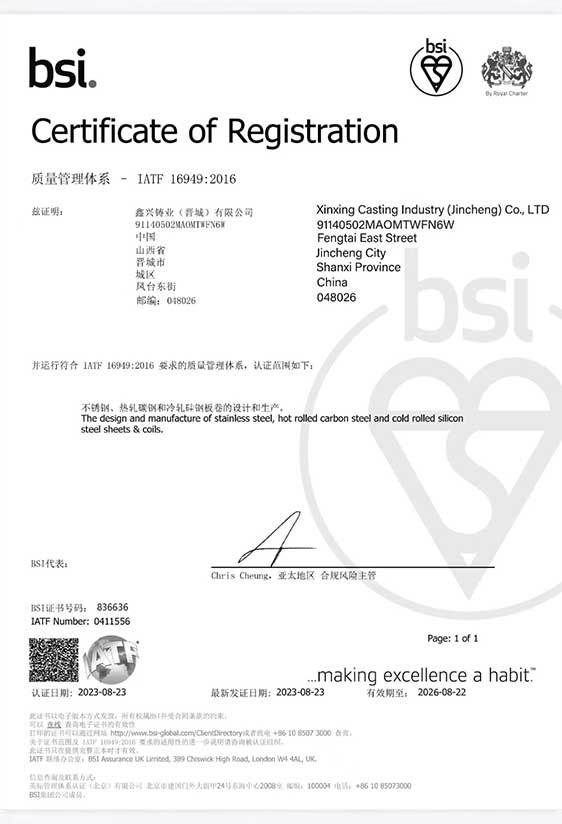

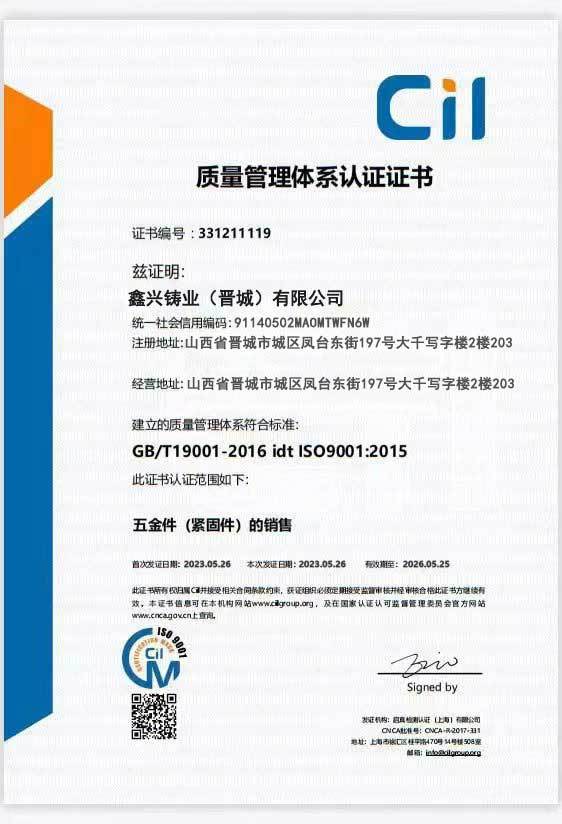

HONOR

RELATED PRODUCTS

GET A FREE QUOTE